Vale Long Harbour Nickel Processing Plant

Client:

Labrador and Newfoundland, Canada

Vale

Location:Labrador and Newfoundland, Canada

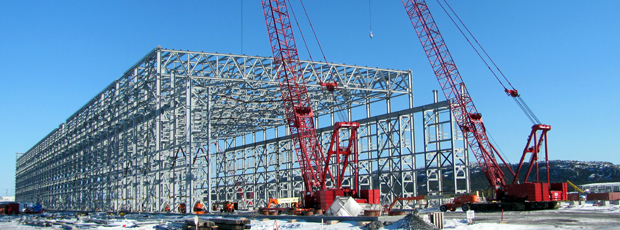

Fluor is performing EPC Services for the Long Harbour Nickel Processing Plant being built by Vale.

The plant will produce 50,000 tonnes per year of finished nickel product, together with associated cobalt and copper products.

The plant will produce 50,000 tonnes per year of finished nickel product, together with associated cobalt and copper products.

Client's Challenge

Brazil-based Vale is the second-largest mining company in the world. Vale’s objective for the nickel processing plant is to process concentrate from the mine / concentrator in northern Labrador to produce finished nickel product and associated cobalt and copper products.

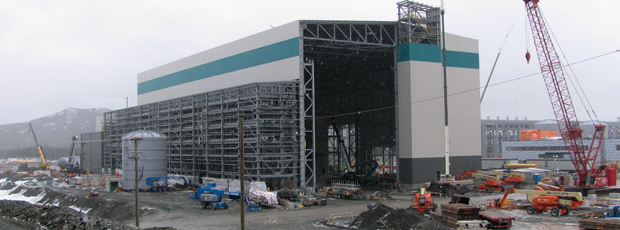

The project is being built on a partially brownfield site near the port of Long Harbour. The plant footprint includes concentrate offloading, crushing, and grinding facilities located near the wharf; the main processing plant located approximately 2 km south of the port facility; a pipeline to supply process water; an effluent discharge pipe and diffuser into the harbour; and a residue pipeline into a nearby disposal area.

The plant site will house a complex process in which concentrate is pressure-leveled in acidic solutions to separate iron, sulfur, and other impurities from nickel, copper, and cobalt.

Project execution will include commitment to a transparent procurement process and promotion of local businesses; critical success factors are high levels of productivity, on-time and under-budget completion, and labour stability.

The project is being built on a partially brownfield site near the port of Long Harbour. The plant footprint includes concentrate offloading, crushing, and grinding facilities located near the wharf; the main processing plant located approximately 2 km south of the port facility; a pipeline to supply process water; an effluent discharge pipe and diffuser into the harbour; and a residue pipeline into a nearby disposal area.

The plant site will house a complex process in which concentrate is pressure-leveled in acidic solutions to separate iron, sulfur, and other impurities from nickel, copper, and cobalt.

Project execution will include commitment to a transparent procurement process and promotion of local businesses; critical success factors are high levels of productivity, on-time and under-budget completion, and labour stability.

Solution

Fluor is performing EPC Services for Vale’s Long Harbour Nickel Processing Plant. The plant comprises a port site and a plant site scheduled for completion in 2013.

The port site facilities are concentrate and limestone offloading facilities and storage, a limestone kiln, concentrate and limestone grinding, sulfuric acid storage and distribution, non-process buildings and utilities, a pipe corridor, and an access road to the process plant.

Process facilities are a pressure oxidation plant that includes an oxygen plant; LRT / CCD; solvent extraction; cadmium removal; and nickel; copper; and cobalt electrowinning. Associated facilities are water and sewage treatment plants, non-process buildings and utilities, residue storage, roads and pipelines, and temporary facilities for use during construction only.

Vale is committed to providing a safe work environment for all employees and subcontractors. As part of that commitment, the companies produced a safety video to be shown to all employees working on the project.

The port site facilities are concentrate and limestone offloading facilities and storage, a limestone kiln, concentrate and limestone grinding, sulfuric acid storage and distribution, non-process buildings and utilities, a pipe corridor, and an access road to the process plant.

Process facilities are a pressure oxidation plant that includes an oxygen plant; LRT / CCD; solvent extraction; cadmium removal; and nickel; copper; and cobalt electrowinning. Associated facilities are water and sewage treatment plants, non-process buildings and utilities, residue storage, roads and pipelines, and temporary facilities for use during construction only.

Vale is committed to providing a safe work environment for all employees and subcontractors. As part of that commitment, the companies produced a safety video to be shown to all employees working on the project.

Conclusion

Once completed, Fluor will deliver to Vale a plant that will process concentrate from the Voisey’s Bay mine / concentrator in northern Labrador to produce 50,000 tonnes per year of finished nickel product, together with associated cobalt and copper products.

Read about other Fluor Constructors projects.

Read about other Fluor Constructors projects.